Ultra Seal Skirts – Revolutionise Conveyor Maintenance Again and Again

An iron-ore mine in WA’s Pilbara approached H & B Mining to seek a better conveyor stacker skirting option

Ultra Seal Skirts – Revolutionise Conveyor Maintenance Again and Again

The ‘Easy Maintenance Model Training Tool’ or EMMTT for short, is a portable, life-size conveyor model specifically designed to train maintenance staff on-site.

Segmented Ultraseal Conveyor Skirt Arrives in WA’s Pilbara

The ‘Easy Maintenance Model Training Tool’ or EMMTT for short, is a portable, life-size conveyor model specifically designed to train maintenance staff on-site.

Training Model Transforms Conveyor Maintenance

The ‘Easy Maintenance Model Training Tool’ or EMMTT for short, is a portable, life-size conveyor model specifically designed to train maintenance staff on-site.

H & B’s ‘Streamline’ is Re-defined

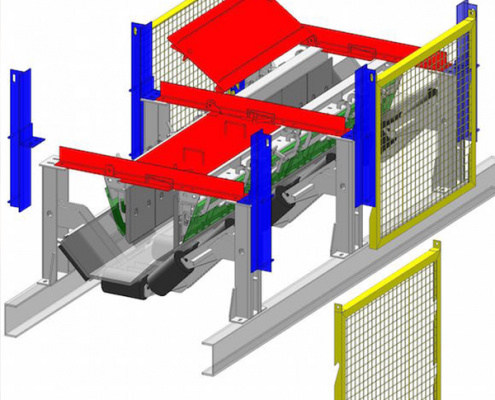

The latest innovation in H & B Mining’s conveyor transfer product range is the Speilbar (false deck) design. Comprehensive conveyor chute maintenance is essential for optimal material flow and containment, and ultimately mine productivity.

How to Complete Roller Change Out with Single-Sided Access:

The latest innovation in H & B Mining’s conveyor transfer product range is the Speilbar (false deck) design. Comprehensive conveyor chute maintenance is essential for optimal material flow and containment, and ultimately mine productivity.

The EMRI has Landed

The latest innovation in H & B Mining’s conveyor transfer product range is the Speilbar (false deck) design. Comprehensive conveyor chute maintenance is essential for optimal material flow and containment, and ultimately mine productivity.

THE E.M.R.I. SUPERSEDES AND REPLACES THE DROP-DOWN IDLER

The latest innovation in H & B Mining’s conveyor transfer product range is the Speilbar (false deck) design. Comprehensive conveyor chute maintenance is essential for optimal material flow and containment, and ultimately mine productivity.

INNOVATION TO IMPROVE CHUTE MAINTENANCE AND SLASH SHUTDOWN TIME

The latest innovation in H & B Mining’s conveyor transfer product range is the Speilbar (false deck) design. Comprehensive conveyor chute maintenance is essential for optimal material flow and containment, and ultimately mine productivity.

UNACCESSIBLE RETURN IDLER ROLLS MADE ACCESSIBLE

H & B Mining’s ‘Easy Maintenance Retractable Idler’ provides safe, simple and quick access to all rollers for maintenance. The original EMRI was successfully adapted for return idler roller maintenance and now the EMRI design has been further modified to suit return idlers with access from one side of the conveyor only.

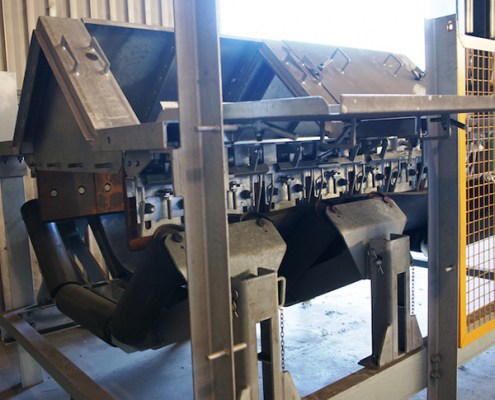

EMRI: THE MULTIPURPOSE RETRACTABLE IDLER

Maintenance crews face many hurdles when maintaining the safety and productivity of conveyor transfer points. Conveyor transfer design with the central need to contain material inherently comes with restricted access and confined spaces, making maintenance a time consuming and difficult process.

HANDS-FREE ROLLER CHANGE-OUT “IT’S THE FUTURE!”

Twenty five years ago H & B Mining developed the first drop down idler (DDI). The DDI revolutionised conveyor roller change out and became a standard inclusion on just about every mine site in Australia.

ULTRASEAL’ SKIRTS THE ULTIMATE SOLUTION FOR EASY CONVEYOR MAINTENANCE

Conveyor skirting systems in high impact transfer areas are notorious for excessive skirt wear and belt tear potential, contributing to excessive material spillage and high maintenance costs.

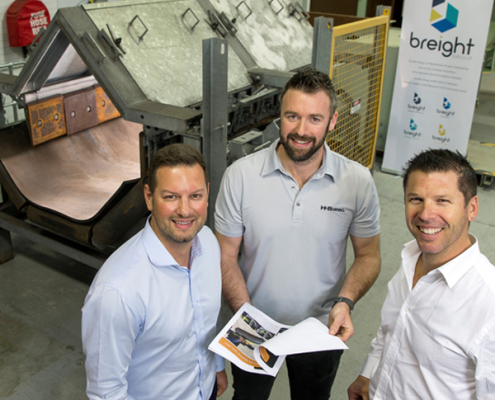

THE SOLUTION FOR CONVEYOR TRANSFER EASY MAINTENANCE: H & B MINING COLLABORATE WITH BREIGHT GROUP.

A deliverable in conveyor maintenance has arrived!

Customised H & B conveyor transfer products have coupled with educated and competent people in maintenance and standardised conveyor practices in a new collaboration between H & B Mining and Breight Group.

“ULTIMATE SEAL” SKIRT LINER - NO MORE GROOVES IN YOUR CONVEYOR BELT

Conveyor skirting system design faces the challenge of forming a seal between the carry belt and skirt liner for the containment of material and dust without creating excessive friction wear to the carry belt itself.

H & B MINING – INSPIRATION TO INNOVATION

H & B Mining have established themselves as innovators in conveyor transfer design through successful design and application of their mining conveyor products in mine-sites around the world over the last 25 years.

PILBARA IRON-ORE INVEST IN H & B’S NON-DROP SKIRT LINER

Ninety nine percent of mining conveyor transfer points experience the problem of skirt liner dislodgement. H & B Mining’s patented non-drop conveyor skirt liner has been identified as the solution to this problem for a West Australian iron-ore mine.

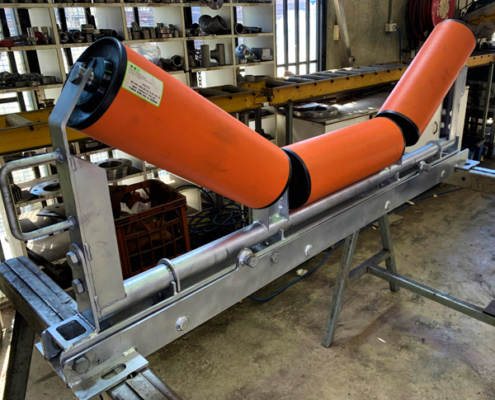

REVOLUTIONARY RETRACTABLE IDLER

H & B's brand new ͚Easy Maintenance Retractable Idler͛, the EMRI will revolutionise conveyor idler roller maintenance.

H & B MINING BREAKS INTO COAL

For over 20 years H & B Mining have been supplying their ‘Easy Maintenance’ conveyor products to the iron-ore industry of Western Australia.

H & B MINING CREATES NEW INSTAGRAM ACCOUNT

H&B Mining have just started an Instagram account. We will be posting images of our innovative conveyor solutions and projects.

THE MISSING PIECE IN OPTIMAL CONVEYOR TRANSFER DESIGN – FOUND

H & B Mining have developed the Streamline conveyor transfer design, with enhanced conveyor productivity in mind, promising minimal conveyor spillage, reduced shutdown time and effective accessibility for maintenance.

THE STORY OF THE H & B DIVERSION PLOUGH

The H & B Mining diversion plough has been successfully installed and operated in over 50 mine sites across Western Australia and is now entering the international market.

WHAT QUESTIONS TO ASK WHEN SELECTING A CONVEYOR TRANSFER DESIGN?

What are the key considerations involved when choosing a conveyor transfer design?

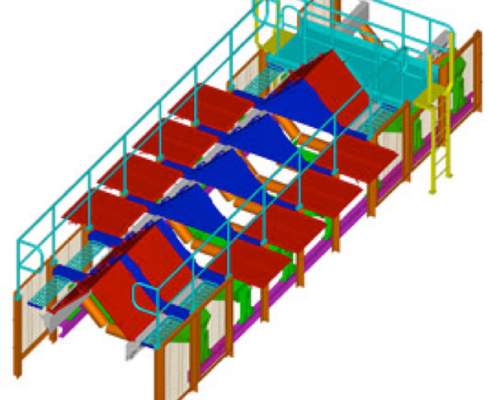

H & B MINING - FULL SCALE CONVEYOR MODEL

H & B Mining have now designed and fabricated a full-scale conveyor model located at the Welshpool workshop. The ‘life-sized’ conveyor product model showcases many of H & B Mining’s innovative conveyor designs.

CONVEYOR TRANSFER POINTS

H & B Mining have over 40 years of experience in conveyor transfer design. We work closely with site personnel and maintenance crews on mine sites across Australia to achieve optimal conveyor transfer design.

MODULAR CONVEYOR DESIGN FOR EASY MAINTENANCE

The easy maintenance modular design for mining conveyors combines the H & B Mining drop down idlers, dust covers and guards together with the standard easy maintenance skirting system bringing consistency in design.

ECO LIGHT SKIRT LINERS

Eco-light Design Future Looks Bright for the ‘Eco Light’. The H & B “Eco-light Skirt Liner” is slowly but surely gaining recognition within the Australian mining industry.

CONVEYOR TRANSFER DESIGN

H & B Mining’s in-house design team designs conveyor transfer points to allow for easy accessibility to maximize maintenance and realise true operational benefits.