Brief Overview

Shut down time for chute maintenance can be massively reduced on multiple feed conveyors by incorporating H&B’s Speilbar (False Deck) design.

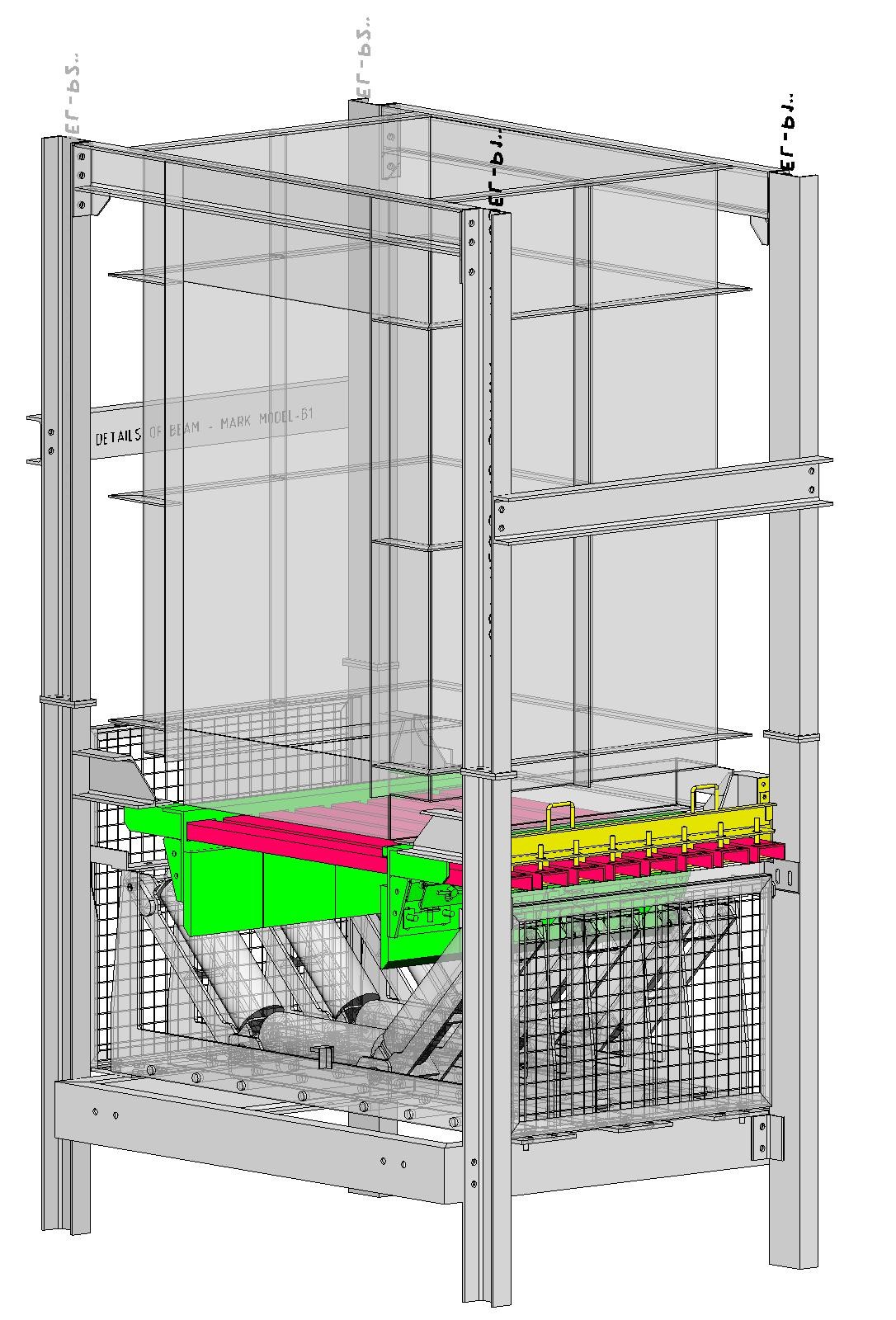

H & B Mining’s latest innovation, Speilbar Design for Transfer Chutes is a revolutionary step forward in conveyor chute maintenance. Comprehensive conveyor chute maintenance is essential for optimal material flow and containment and ultimately mine productivity. Shut down time for chute maintenance can be massively reduced on multiple feed conveyors by incorporating H&B’s Speilbar (False Deck) design.

The H & B Speilbar design creates a false deck inside and below the chute area allowing maintenance personnel access into the chute to perform chute maintenance while the conveyor is operational. The Speilbar design enables access to ALL chute liners.

Custom designed Speilbar skirts are installed into the existing conveyor skirting system below the transfer chute. The Speilbar skirts are designed to receive and hold in place a series of light duty Speilbars which when installed form a false deck. Included in the design is a Speilbar locking mechanism; once the Speilbars are locked in place, access into the chute is made possible.”

Shut down time for chute maintenance can be massively reduced on multiple feed conveyors by incorporating H&B’s Speilbar (False Deck) design.

Reasons to use Speilbar Design for Transfer Chutes:

If you have any questions about our products or services then please don’t hesitate to contact us.

| Title | Download |

|---|---|

| H & B Speilbar Brochure | DownloadPreview |

7 41 Division Street,Welshpool,

Perth, Western Australia 6106

7 Tahiti Lane, Hillarys, Perth, Western Australia 6025