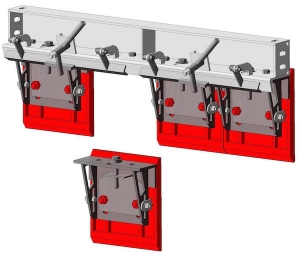

The key design point of the H & B segmented skirts are the detachable skirt segments (to which the skirt liners are attached) which allow for a single operator inspect and change out worn or damaged conveyor skirt liners safely within a matter of minutes from outside of the skirted area.

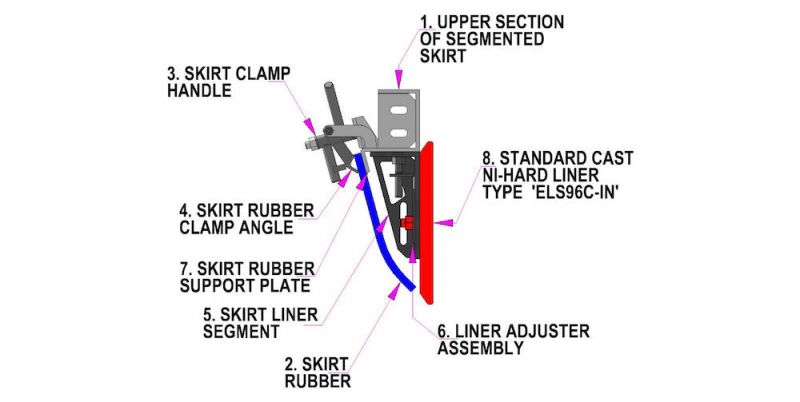

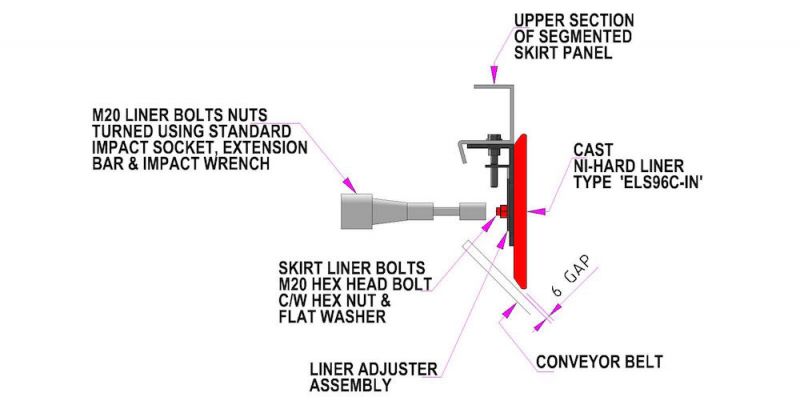

The development of the Segmented Easy Maintenance Conveyor Skirt System heralds a dawn of the changing out of conveyor skirt liners from the outside of chute and skirted areas. Whilst all of the recognised Easy Maintenance features of the H & B conveyor skirt remain, for example the skirt rubber clamping system and vertical liner adjustment, having the ability to access skirt liners externally is an enormous step forward in terms of safety and time saving in mining conveyor maintenance.

An individual can simply inspect and change out worn or damaged conveyor skirt liners safely and within a matter of minutes without the requirement of a confined space entry permit. By utilising the H & B eco-light skirt liner with the segmented conveyor skirt system design, the combined mass of the skirt liner and removable skirt panel is reduced by 40% making all lifts below 20kg.

The eco-light skirt liner is a cast ni-hard liner and when supplied is 100% compatible with mine standard conveyor skirt liners. The eco-light has the same longevity and performs the same function as all standard conveyor skirt liners. This innovative step forward in conveyor skirt maintenance will make conveyor transfers safer, cleaner and more productive.