FREQUENTLY ASKED QUESTIONS

HOW CAN WE INCREASE THE LIFE OF OUR SKIRT LINERS?

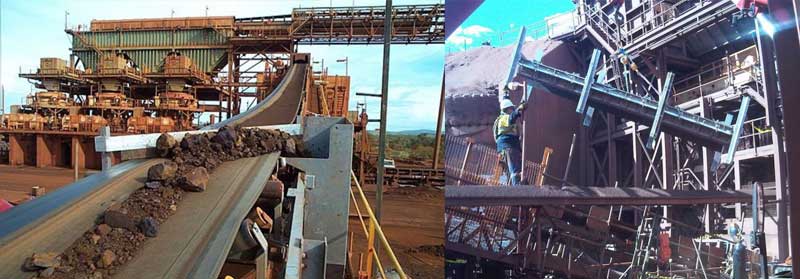

The purpose of a conveyor skirting system is to contain material on the conveyor belt which means only the bottom edge of the skirt liner should be subjected to wear from the belt. The easy maintenance conveyor skirting system is designed so the worn skirt liners can be lowered to close up the gap created between the conveyor belt and the skirt liner.

Utilising the skirting system capability to lower the worn liners, coupled with selecting the reversible symmetrical skirt liner design will double the lifespan of the skirt liner. When the liner has been lowered as far as possible, the reversible skirt liner can be dismantled and reinstalled, therefore doubling its lifespan.

HOW CAN WE REDUCE SPILLAGE?

Maintaining the belt line between skirt liners and impact rolls is the only way to reduce spillage to an absolute minimum. Having the ability to maintain the gap between the skirt liners and the impact rolls is made easier by installing Easy Maintenance Conveyor Idlers where the idler can be dropped down, and the worn and damaged rolls replaced.

By combining this with the easy maintenance conveyor skirting system, where the worn skirt liners can be lowered, guarantees a tight seal along the conveyor belt line. When incorporating the easy maintenance skirting system with the easy maintenance idlers it reduces conveyor belt spillage to an absolute minimum.

HOW CAN WE GET WATER OFF THE CONVEYOR CARRY BELT?

Water can be removed by installing a carry belt diversion plough down stream from the problem area. The diversion plough lays dormant beneath the operational conveyor belt until the tilt idlers are rotated into vertical position causing the profile of the carry belt to change and springing the diversion plough into operation. The water is diverted off the belt down a diversion chute via the plough scraper interacting with the modified belt profile.

HOW CAN MINING CONVEYOR MAINTENANCE TIMES BE REDUCED?

Installing easy maintenance conveyor idlers, skirts, dust covers and guards at your transfer areas will make conveyor system maintenance easy, quick and safe. All H & B mining conveyor products are able to be maintained without the use of cranes or spanners which simplifies the maintenance procedure and reduces shut down times.

DOES H & B SITE INSTALL THE PRODUCTS THEY SUPPLY?

H&B provides a design service and manufactures all of its own products. However, H&B do not provide an installation service. To aid with the installation of all projects completed, a detailed installation procedure is supplied to the client.

Latest News

WORKSHOP

7 41 Division Street,Welshpool,

Perth, Western Australia 6106

- Tel: 08 9403 2993

- info@handbmining.com.au

HEAD OFFICE

7 Tahiti Lane, Hillarys, Perth, Western Australia 6025

- Tel: 08 9403 2993

- info@handbmining.com.au