Brief Overview

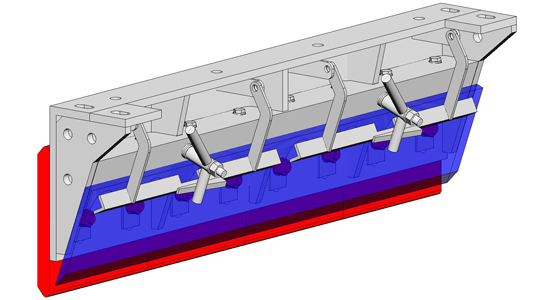

The EMS Conveyor Skirt provides a material containment system which allows for adjustment and replacement of skirt rubber and skirt liners externally.

The ‘Easy Maintenance’ conveyor skirting system is designed with an adjustable primary and secondary seal which allows easy access for inspection and maintenance to the conveyor skirt liners. A single person can remove skirt rubber and inspect the conveyor skirt liners without having to get inside the chute and/or the skirting area.

Once the inspection is complete, the operation to adjust the vertical height of the skirt liners and maintain the all important sealing gap between the skirt liner and conveyor belt still only requires one person. The ‘Easy Maintenance’ conveyor skirting system allows for simple, quick and safe maintenance of skirt liners. This reduces spillage from the conveyor belt down to an absolute minimum and eliminates build up of material around conveyor transfer areas.

The ‘Easy Maintenance’ conveyor skirting system is designed to suit each client’s requirements and can be supplied in complete skirt panel units or simply as loose components ready to be retrofitted to existing skirt boards.

The ‘Easy Maintenance’ conveyor skirting system is a patented product of H & B Mining.

The EMS Conveyor Skirt provides a material containment system which allows for adjustment and replacement of skirt rubber and skirt liners externally.

Reasons to use The ‘Easy Maintenance’ conveyor skirting system:

If you have any questions about our products or services then please don’t hesitate to contact us.

7 41 Division Street,Welshpool,

Perth, Western Australia 6106

7 Tahiti Lane, Hillarys, Perth, Western Australia 6025