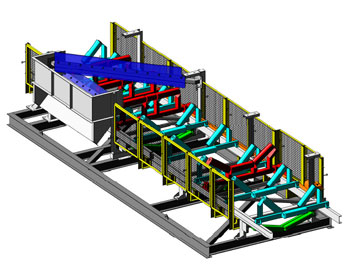

The conveyor diversion plough (plow) was developed and is used to create a secondary circuit on any fixed mining conveyor. It is able to remove or divert any unwanted material from a carry belt. The tilt idler mechanism which lays dormant beneath the operational conveyor is rotated into an operational position by raising the conveyor belt to create a flat surface and then engage with a fixed diverter plate. On small belts the tilt idlers can be rotated into position manually by using a lever system. Alternatively for the larger belts the tilt idlers can be raised via hydraulic or electrical devices.

The H & B Mining conveyor diversion plough provides a solution by creating a secondary circuit for removal of unwanted material on the conveyor.

The H & B Diversion Plough has been designed and supplied within Australia and internationally for a variety of materials including iron-ore, cement, bauxite and fertiliser.