H & B Mining have developed the Streamline conveyor transfer design, with enhanced conveyor productivity in mind, promising minimal conveyor spillage, reduced shutdown time and effective accessibility for maintenance.

The H & B Mining diversion plough has been successfully installed and operated in over 50 mine sites across Western Australia and is now entering the international market.

What are the key considerations involved when choosing a conveyor transfer design?

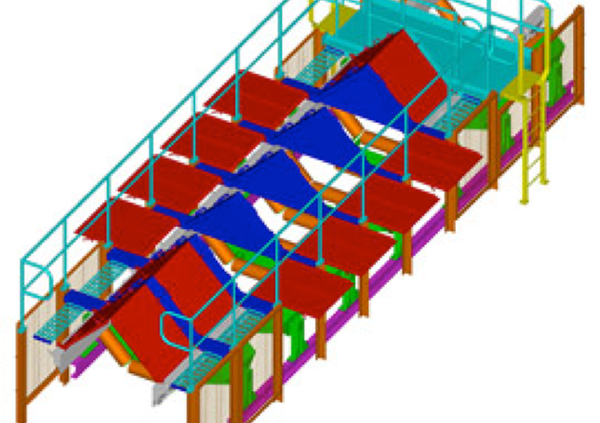

H & B Mining have now designed and fabricated a full-scale conveyor model located at the Welshpool workshop. The ‘life-sized’ conveyor product model showcases many of H & B Mining’s innovative conveyor designs.

H & B Mining have over 40 years of experience in conveyor transfer design. We work closely with site personnel and maintenance crews on mine sites across Australia to achieve optimal conveyor transfer design.

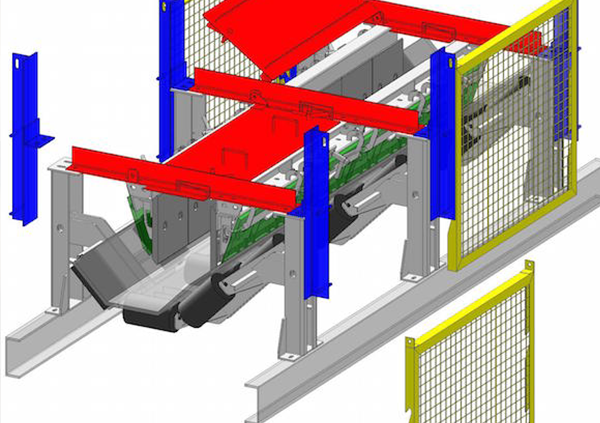

The easy maintenance modular design for mining conveyors combines the H & B Mining drop down idlers, dust covers and guards together with the standard easy maintenance skirting system bringing consistency in design.

Eco-light Design Future Looks Bright for the ‘Eco Light’. The H & B “Eco-light Skirt Liner” is slowly but surely gaining recognition within the Australian mining industry.

H & B Mining’s in-house design team designs conveyor transfer points to allow for easy accessibility to maximize maintenance and realise true operational benefits.