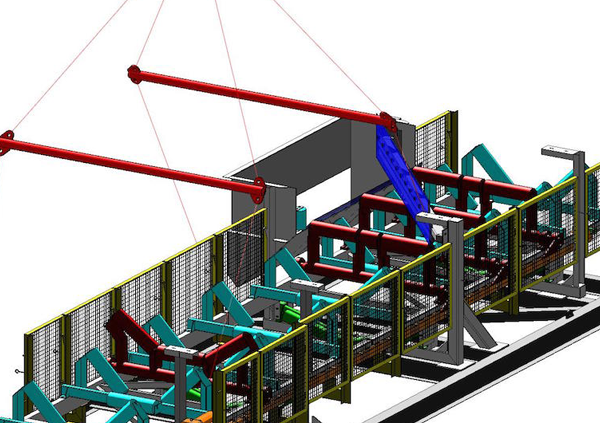

H & B Mining have just completed fabrication of a conveyor module which includes a carry belt diversion plough as an integral part of the design for Jimblebar Stage 2.

H & B Mining have been identified as the Experts in Conveyor Skirts for a problematic conveyor transfer point at the Rio Tinto bauxite operation on the Gove Peninsula in the Northern Territory.

Mining conveyor diversion ploughs are a specialised field in conveyor design – H & B Mining are establishing themselves as experts in this area.

Rio Tinto Alcan has employed H & B Mining as part of the redesign for conveyor transfer points at their Gove Operations bauxite mine in the Northern Territory.

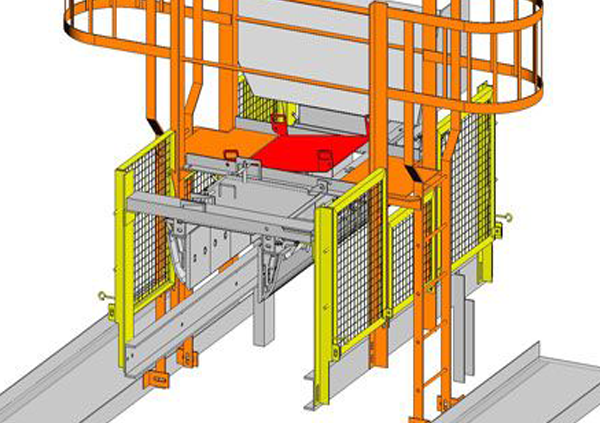

H B integrated conveyor crossoverTheBHP Billiton recently activated conveyor M236 at Mt Whaleback, Western Australia.

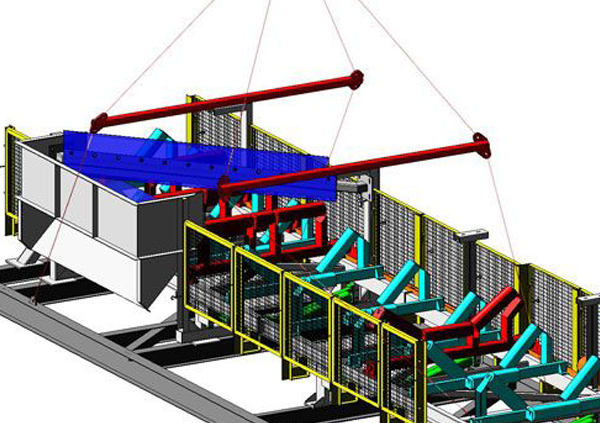

Stage 2 is at last underway at Jimblebar iron-ore mine in the Pilbara of Western Australia! H & B were nominated by BHP Billiton as the preferred client for the design and supply of the carry-belt diversion plough for conveyor CV002.

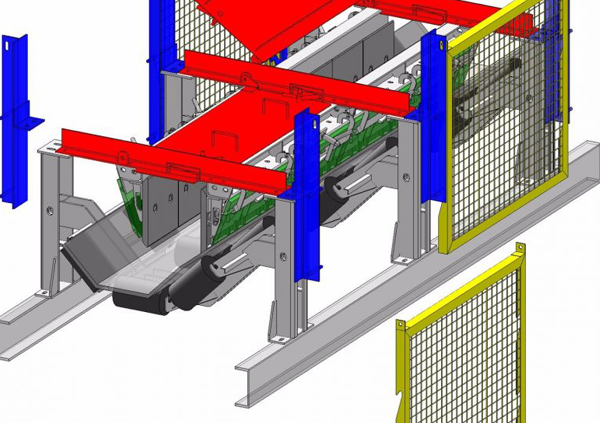

As part of an ongoing upgrade maintenance crews at BHP Billiton decided to upgrade Conveyor Transfer M233 at Mt Whaleback.

Twenty two years in the conveyor transfer design and supply business and H & B Mining find themselves in the enviable position of supplying Roy Hill with four of their seven ‘Easy Maintenance’ conveyor products which are currently available to the Australian mining industry.

The introduction of the innovational modular skirt, hinged cover and DILO guarding system for Conveyor M232 at Mt Whaleback has been hailed a revelation.