Brief Overview

The novelty in the H & B Eco-Range skirt liner is that the liner is designed to accommodate commercial bolts to fix the liners in place.

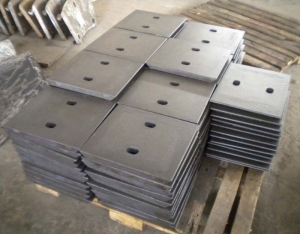

CONVEYOR SKIRT LINER – ‘ECO’ DESIGN BY H & B

The novelty in the H & B Eco-Range skirt liner is that the liner is designed to accommodate commercial bolts to fix the liners in place. The Eco Skirt Liner products are designed to suit the client’s needs with economy and safety in mind

The Eco Standard Conveyor Skirt Liner is a full-thickness, cast ni-hard liner designed for impact areas. It’s ability to utilise a commercial bolt reduces supply costs.

The Eco-light Skirt Liner is a hollowed, cast ni-hard liner designed economy and safety in mind for low impact areas. Whilst performing its primary task of containing material along the conveyor belt, this innovative design reduces the overall mass of the skirt liner by up to 40%. Therefore, this conveyor skirt liner is safer to handle whilst reducing supply costs at the same time.

ADVANTAGES OF THE ECO-LIGHT CONVEYOR SKIRT LINER

The ‘Eco-light’ conveyor skirt liner is a patented product of H & B Mining.

The novelty in the H & B Eco-Range skirt liner is that the liner is designed to accommodate commercial bolts to fix the liners in place.

Reasons to use H&B Ecolight Conveyor Skirt Liners

If you have any questions about our products or services then please don’t hesitate to contact us.

7 41 Division Street,Welshpool,

Perth, Western Australia 6106

7 Tahiti Lane, Hillarys, Perth, Western Australia 6025